Qualification and Validation are crucial components of all quality assurance processes.

At Boedeker Plastics, Inc. we utilize a wide variety of qualifications and validations during different stages of production. The three main stages include IQ (Installation Qualification), OQ (Operational Qualification), PQ (Process Qualification).

Other types of qualifications and validations we perform include; Process Flow Plan, pFMEA (Process Failure Mode Effects Analysis), Control Plan, Process Materials Contact List, RoHS, REACh, Animal Derivatives and Gage Certifications.

Customer Specific Full Process Design Qualification and Validation Services

For clients with unique validation requirements we offer a customizable Full Process Design Qualification and Validation Services with options for their specific requirements. This service is available to our customers and is based on their unique requirements, additional costs vary depending on the customers’ unique qualification and validation requirements. This typically involves a validation plan, programming for CNC and quality equipment, initial dimensional and visual checks, and any documentation such as pFEMA, REACh, etc. needed.

IQ (Installation Qualification) Examples- Machine set up and installation is key for manufacturing equipment to deliver a desirable result.

IQ is the 1st step in the validation process to ensure that the manufacturing process operates within the expected parameters. In the IQ phase the equipment’s design features are checked to make sure they were installed correctly against equipment documents, drawings and manuals. During the IQ validation process, equipment maintenance and calibration schedules and procedures are established. All gages are calibrated and documented for all our CNC equipment. Some examples of items that are part of the IQ process for our CNC equipment includes: electrical supply, air supply, environmental conditions, space requirements, lighting conditions, safety, preventative maintenance, coolants and lubrications.

OQ (Operational Qualification) Examples - Test runs are used to determine the operational qualifications for manufacturing equipment and software.

OQ is the 2nd phase of validation we use to verify that the manufacturing process is achieving its operational requirements. We perform test runs to determine the highest, lowest and medium operating parameters. This data is used to set control limits and action limits for our process parameters. This set ensures that the process is repeatable. The process is challenged to define worst case conditions. After successful OQ, the process control limits are validated with action levels result in product that meets all defined requirements. All gages used are calibrated and documented during this process. Some examples of items that are part of the OQ process for our CNC equipment and software include: safety, spindle speed, spindle runout at taper, spindle runout on test bar, spindle draw bar load, level, ball bar test as well as program loading (software validation/black box approach).

PQ (Process Qualification or Validation) Examples – Specific functions are challenged under normal and anticipated operating conditions.

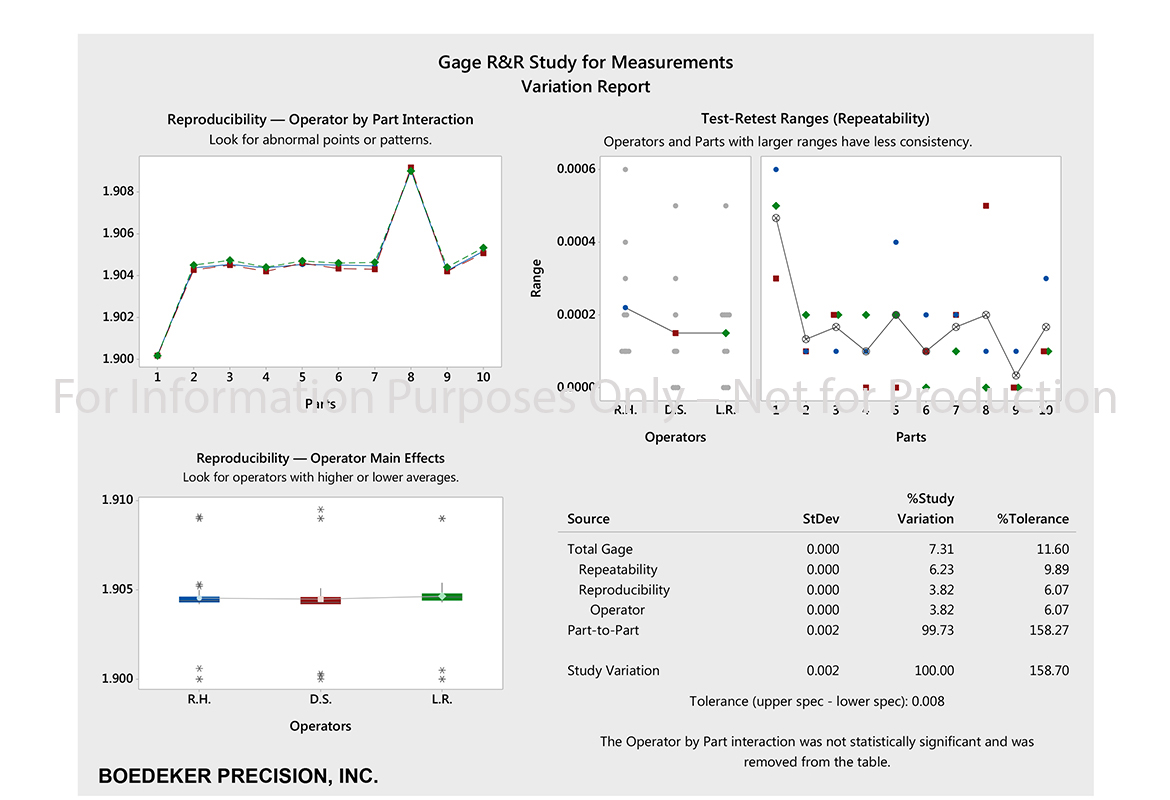

PQ is the last phase of the validation process for our manufacturing and metrology equipment. In this phase equipment and manual processes are run multiple times under normal operating conditions to challenge specific functions. This phase Examples of typical functions that are challenged include, precision (tolerances) and repeatability. PQ demonstrates that the process, under anticipated conditions, consistently (long term runs) produces a product which meets all predetermined requirements for functionality and safety. In this phase Two main items that undergo PQ include metrology equipment and CNC manufacturing processes. Our metrology equipment is subjected to a measurement systems analysis that we report using Minitab, as shown in the below screen shot.

The below report shows a variation report for a typical Gage R&R study for measurement accuracy.

Some of the common measurement systems analysis we perform include Gage R&R, Attribute Analysis and Bias Study.

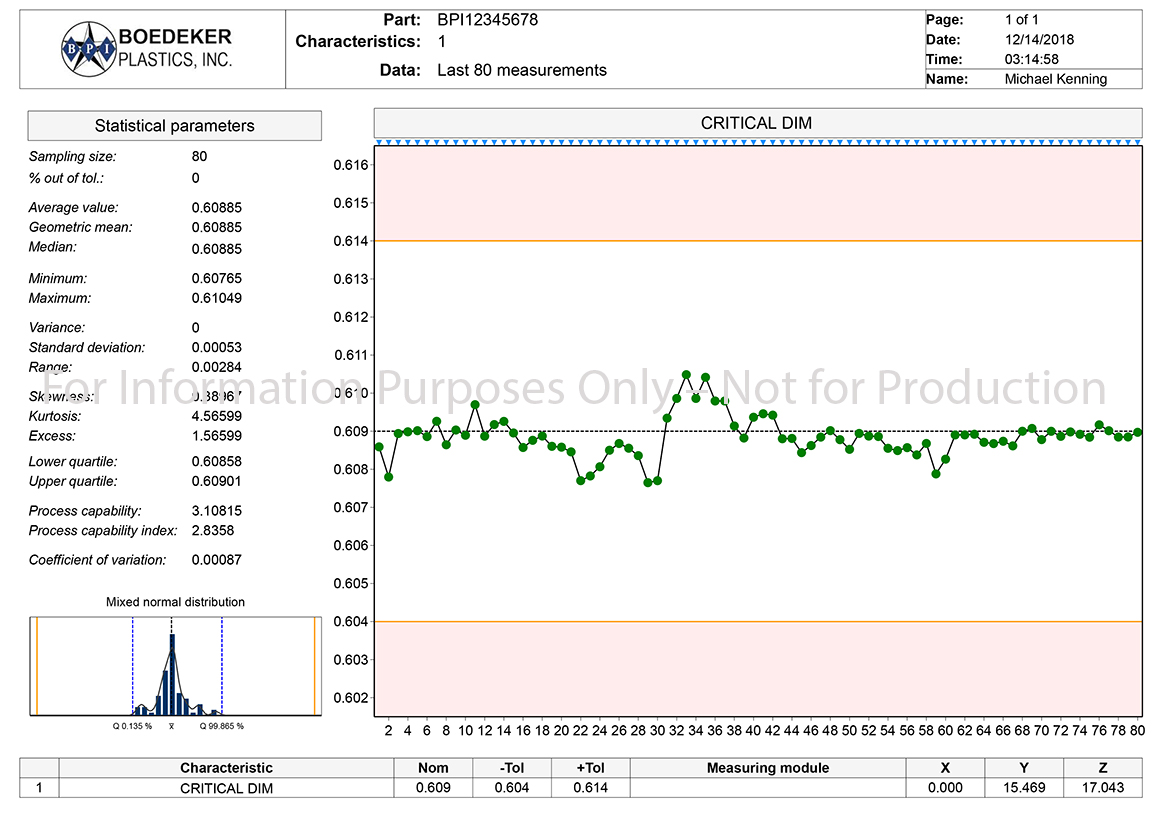

Below is a sample of a Process Capability report showing statistical data for sample size of 80 measurements taken from of a single critical dimension.

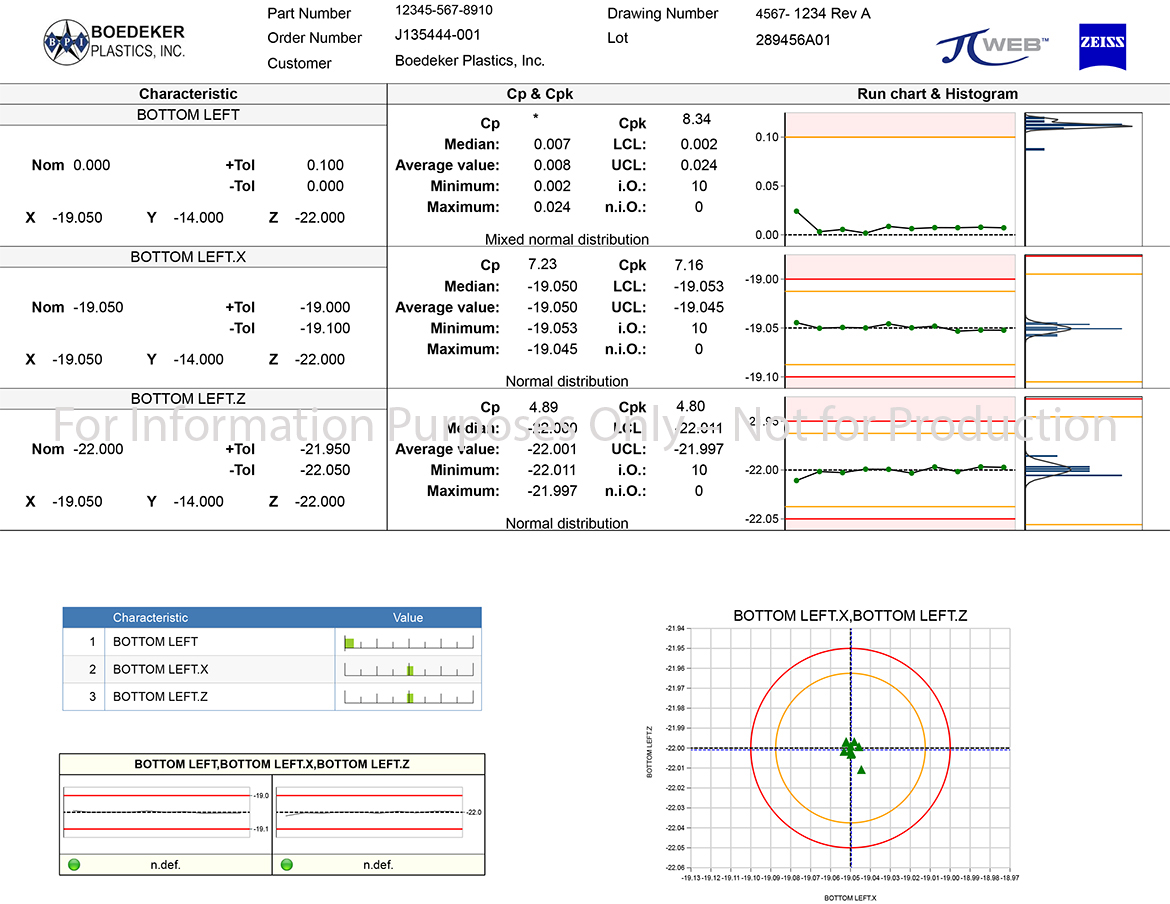

Process Qualification (PQ) is performed on our CNC manufacturing processes and reported using Minitab and πWeb and reported in capability (CP and CpK) and/or performance (Pp and Ppk) ratios for validation analysis.

Below is a typical report that shows the Cp and CpK ratios.

Summary

We have a wide range of qualification and validation services and work closely with our customers in providing these services based on their unique requirements. Contact Us to explore your specific qualification and validation requirements for a customized quote for the manufacture of your parts and a customized qualification and validation plan.