What is Water Jet Cutting?

Water Jet cutting is a CNC (Computer Numerical Control) subtractive manufacturing machining technology, which utilizes a high-pressure stream of water and abrasive media to erode a narrow cut to create profiles, circles and other geometries into thin to thick flat material stock.

This technology can be used to cut a wide range of materials including: foam, plastic, composites, tool steel, titanium and many others. Waterjet cutting typically involves cutting 2D geometries such as through holes or profiles out of flat material stock. In recent years, advancements have brought multi axis articulating heads to accommodate 3D geometries like bevels, chafers and intricate shapes. In addition, rotary axis is now available to accommodate tube and pipe stock.

When to use Water Jet Cutting?

This process is ideal for small to large parts with 2D holes, profiles and other 2D geometry with low to medium tolerances.

Why use Boedeker Plastics, Inc. for plastics or composite Water Jet Cutting?

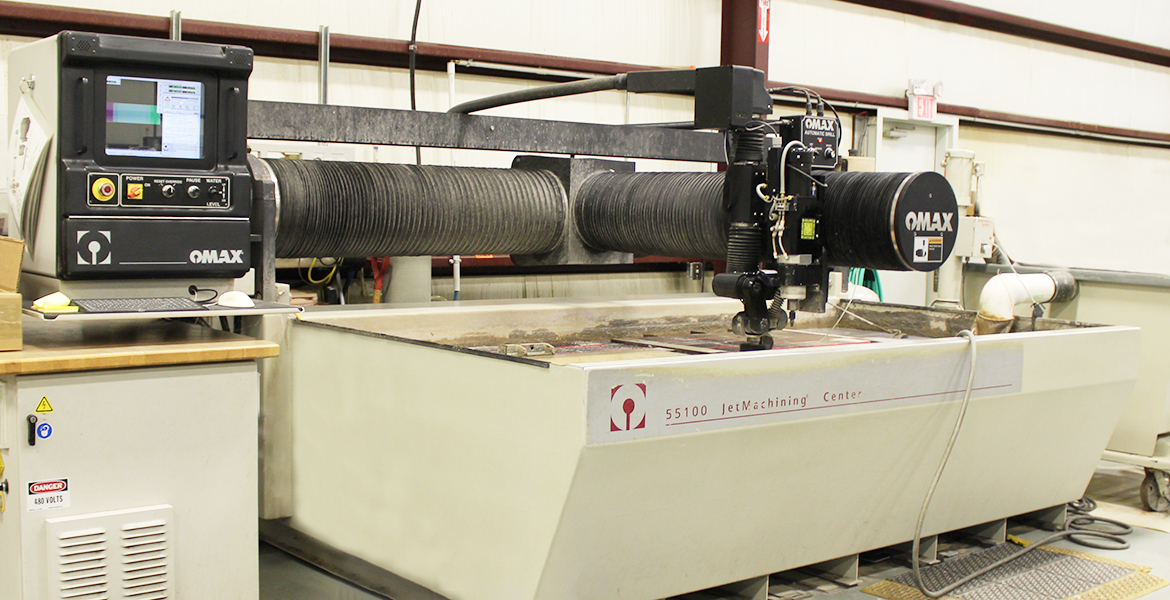

Our shop utilizes a OMAX JetMachining Center for waterjet cutting parts up to 6" thick that is backed by years of experience in plastics & composites only waterjet cutting. We have the experience, personnel & technology to provide reliable supply of high quality CNC machined plastic & composite parts. We also specialize in providing clients with Just in Time Supply (JIT) inventory services to help reduce inventory costs and provide parts as needed without long lead-times.

Our Water Jet Equipment

- Waterjet OMAX JetMachining Center

Some of the Plastic & Composite Materials We Specialize in Water Jet Cutting & Machining Include: