What is CNC Turn / Milling?

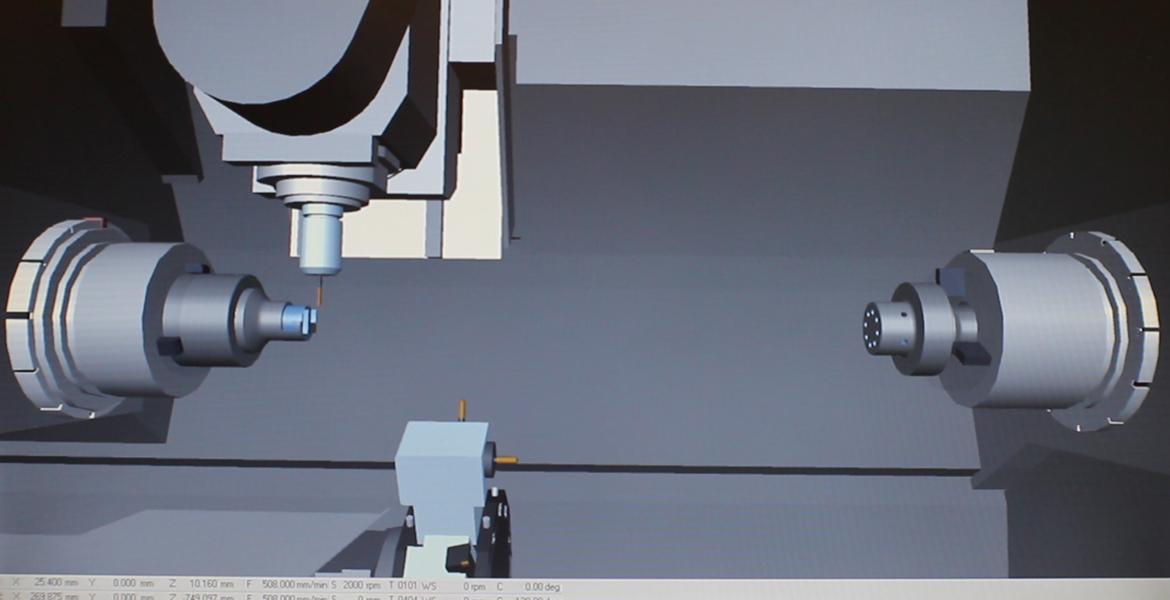

Turn / Milling is a hybrid CNC (Computer Numerical Control) subtractive manufacturing machining technology that combines turning and milling operations into one machine, which combines a lathe’s chucks and spindles with the capabilities and milling power of a machining center.

When to use CNC Turn / Milling?

This process is ideal for parts that have both turning and milling steps, high part volume, complex geometries requiring multi-axis machining and tight tolerances.

With its multi-tasking capabilities, it requires only one machine set up and produces parts with faster cycle times when compared to utilizing a separate lathe and milling machine. Another advantage is eliminating multiple set-ups which can also introduce tolerance error.

Why use Boedeker Plastics, Inc. for plastics or composite CNC Turn / Milling?

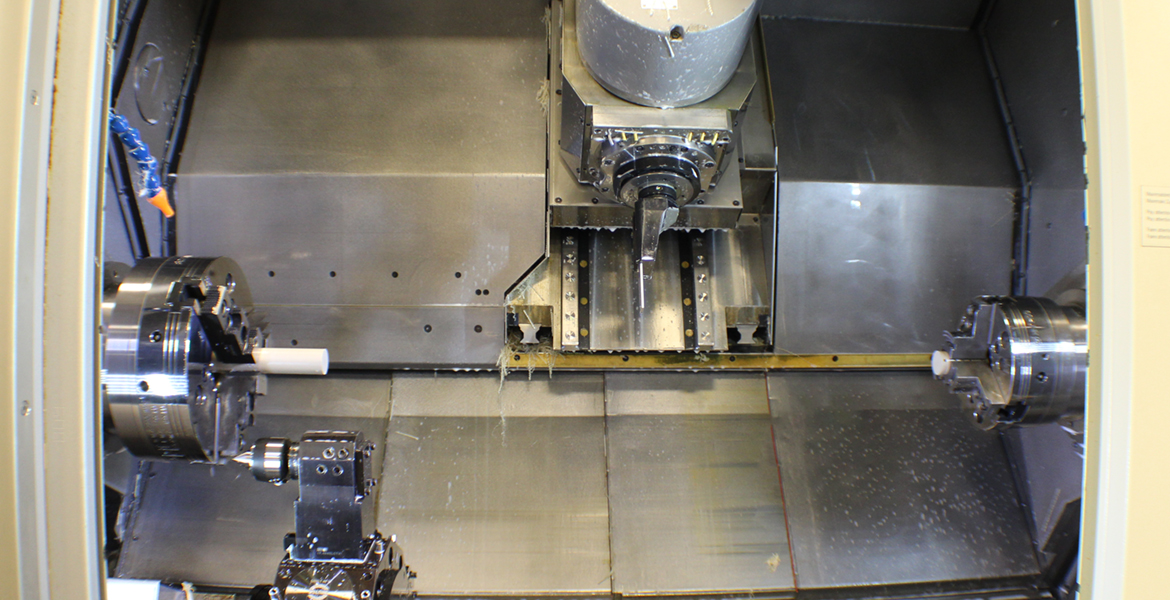

Our shop has several CNC Turn / Milling Machines which are backed by years of experience in plastics & composites only CNC machining. We have the experience, personnel & technology to provide reliable supply of high quality CNC machined plastic & composite parts. We also specialize in providing clients with Just in Time Supply (JIT) inventory services to help reduce inventory costs and provide parts as needed without long lead-times.

Our Turn / Milling Equipment

- Gildemeister CTX 410 Lathe

- Gildemeister CTX 420 Lathe

- Gildemeister GMX 250 Linear Lathe

- HAAS - ST30SSY Lathe

Some of the Plastic & Composite Materials We Specialize in Machining Include: