What is Onshoring / Reshoring and how does it differ from Offshoring?

Offshoring

For over the last twenty years many US based manufacturers have been “offshoring” various in-house manufacturing and business operations to other countries including: Mexico, Canada, China, Malaysia, Vietnam, India and many other countries. Offshoring was mainly driven by reducing costs with lower labor prices or other lower cost-based incentives. With offshoring the lower costs sometimes have a trade off with quality issues, communication issues, slower response time and longer lead-times. When a company outsources work outside of its home country it is known as offshore outsourcing.

Onshoring / Reshoring

Onshoring, which is also known as Reshoring is the opposite of Offshoring. This is the business process of bringing in-house manufacturing or business operations back to the US (or a business’s home country). With rising labor costs in foreign countries and issues with quality, communication, lead-times, changing tariffs and restrictions with certain countries, many US based companies are bringing their in-house business and manufacturing operations back to the US. In addition, they are onshoring their outsourcing requirements with domestic US based businesses, which is known as onshore outsourcing, reshoring outsourcing or domestic outsourcing.

Advantages to Onshoring / Reshoring and Onshore Outsourcing?

Communication

Offshoring comes with the major risk of communication issues, which can lead to distrust and cause a breakdown in communication with a negative impact on productivity and quality. Onshoring with in-house manufacturing or an outsource supplier in the businesses’ home country avoids these issues by eliminating the foreign language barrier. Also, the issues with major differences in time zones are eliminated, which greatly improves communication and response times.

Cultural Differences

Cultural differences can be a major source of offshore outsourcing problems. Onshoring and onshoring outsourcing eliminates these issues. With Onshoring the business or outsource partners share the same holidays as their customers, while offshoring typically will result in different holidays which causes issues with availability to deal with potential increased production requirements during that time or being available during that time to handle emergencies or customer issues. In some cases, offshoring can result in a different approach to manufacturing and business. In some cultures, feedback related to finished products may not be welcomed and be considered a break in protocol and be considered criticism of their manufacturing or business processes.

Cost Savings

The main driver for offshoring has been to reduce cost by taking advantage of lower labor costs and incentives offered by foreign countries. The true cost of offshoring can be higher when you factor in the costs of overseas travel to deal with problems, lost time due to communication and cultural differences, ramp up time educating the offshore staff regarding your company’s procedures and protocol and in some cases rising tariffs and changing incentives for businesses in their home country to bring manufacturing and business back to their home country.

Quality

Onshoring and onshoring outsourcing is more effective and easier to deal with when maintaining quality systems and dealing with quality issues. In the case of training and maintaining quality systems, onshoring provides an efficient and lower cost path as it is not burdened with communication barriers, cultural differences and response times related to different time zones. The cost of slow response times to quality issues with customers can greatly impact future sales, resulting in lost revenue and increased costs in resolving those problems.

Protection of Intellectual Property

Intellectual (IP) and copyright laws are different from country to county. In most cases, other countries don't enforce these laws the same way as the USA does, which results in risk that the offshore organization or offshore outsourcing partner will have access to their sensitive data and it can be used to compete against them. The United States has much stronger legislation to protect IP and enforce copyright laws, which provides greater long-term protection to a USA based company by eliminating the competitive threat of stolen IP being used against them.

What are the advantages of Boedeker Plastics, Inc. as an Onshoring / Reshoring outsource partner for your complete plastic and composite materials and parts needs?

Boedeker Plastics, Inc. is an American-owned and operated company with an expert staff with over 500 years of combined plastics experience. We offer all the many advantages listed above for any company seeking a complete plastics solutions onshore / reshoring outsource partner. We offer a complete plastics solution the Boedeker Way, with an experienced and dedicated staff offering plastic and composite shapes, machined plastic and composite parts and injection molded plastic parts, JIT supply, technical services and much more.

Dedicated Experienced Staff

Our staff is comprised of over 150 employees with over 50 dedicated to sales and engineering support for our clients. On average each employee has over 20 years’ experience in plastics, at Boedeker Plastics, Inc. we have very low turnover which provides our customers access to a stable and highly skilled technical sales staff. This allows our customers to develop a solid long-term relationship for years to come. You’ll always know who to talk to and your representative will always know you, your business and your needs.

Quality

Our facility is ISO 9001 & 13485 certified, ITAR Registered, 21 CFR 820 Compliant and FDA registered. Our Quality Assurance is backed by a Team of Quality Professionals that utilize a wide range of metrology equipment and software. From hand tools to state of the art image and coordinate measurement machines (CMMs) we have the personnel and technology to ensure the highest levels of quality.

Learn More About Our Quality Assurance

Plastic & Composite Sheet, Rod, Tube & Custom Profiles Supply Services

We are a leading master distributor of plastic and composite semi-finished sheet, rod, tube and custom profile. We specialize in Service & Support and offer over 20 million dollars of inventory in plastic and composite shapes backed by years of experience with cut to size and same day shipping service and full traceability. Our inventory and service allow you to maximize yields, reduce costs and eliminate lead-time headaches backed by our experienced staff.

Learn more about our Plastic & Composite Supply Services.

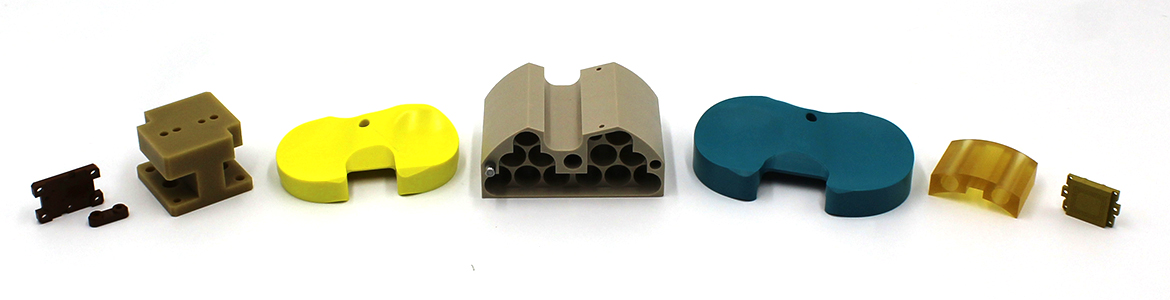

Plastics Only CNC Machined Plastic & Composite Manufactured Parts Supply Services

We specialize in plastics and composite only CNC machining with over 100 CNC machines backed by experienced personnel. We offer prototype to high volume production services. We work closely with many of our clients on prototypes during the initial stages of product development assisting with material selection and design to maximize machined part manufacturability and performance.

Learn More About our Plastics & Composites Only CNC Machining Services

Injection Molding Manufactured Parts Supply Services

For customers that require higher volume plastic parts we offer custom injection molding. We offer in-house Engineering Services with mold flow analysis (MFA), finite element analysis (FEA) and can assist with optimizing part design to reduce production costs and maximize part performance. We specialize in high performance materials and offer quick turn tooling, insert molding, over-molding, near-net shape molding and other injection molding related services.

Learn More About our Injection Molding and Related Services

Just in Time (JIT) & Master Supply Agreement (MSA) Supply Services

With our JIT Supply Services, customers’ parts are inventoried and released as needed, just in time for production, to eliminate the costs associated with carrying large on hand inventories at the customer’s facility. JIT Supply provides reliable, consistent, high-quality supply and eliminates long lead-times. We also offer Master Supply Agreements, that consolidate supply of our customers’ overall plastic & composite material or part requirements. This results in reduced cost by consolidating vendors, reduced on-hand inventory at the customer, and in many cases, provides reduced material or part price. Customers with multiple locations benefit with standardized pricing, enhanced quality control and reliable JIT supply.

Learn More About our JIT & MSA Supply Services

Technical Services – Save Time & Money When Selecting Plastics by Application and Optimize your Part Design for Optimal Manufacturing Costs

We offer a variety of technical services to assist our customers with material selection and design to help maximize part performance when using plastics and composites. We can help in assessing all application parameters to help select the best plastic or composite material candidates for testing in your application. In many cases, plastics and composites are ideal choices for metal replacement or upgrading the existing plastic or composite for enhanced part performance and extended part life in process. We assist customers with part design to ensure realistic tolerances and the correct geometries are considered when designing with plastics or composites, to eliminate excessive manufacturing cost or potential issues with failure when the part is machined or molded during production or in the field. We work closely with our customers to control part cost and evaluate alternative manufacturing processes as the part transitions from prototyping to machining to injection molding. In some cases, it is possible to streamline part design and eliminate features that create additional un-needed cost in manufacturing.

Learn More About our Technical Services

We stand ready to assist you with your Onshoring / Reshoring plastics related needs and welcome the opportunity to evaluate your requirements with our complete plastics solutions services.