Complete Custom Injection Molding Solutions | ISO Certified

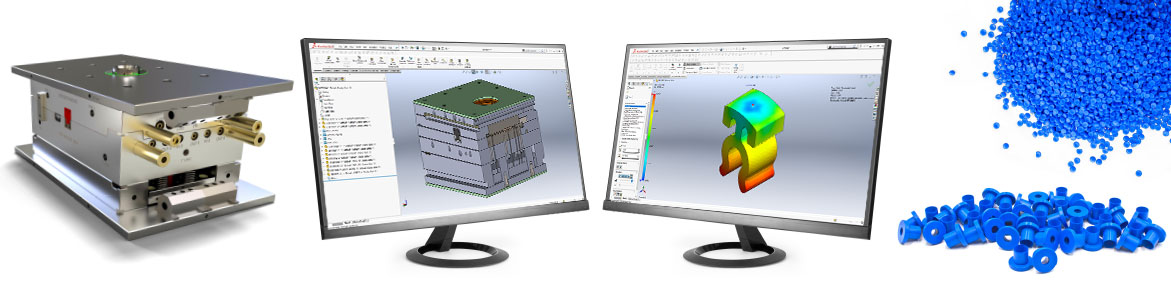

In-House Mold / Tooling Design, Mold Flow Analysis & FEA

Get it Right the 1st Time and Reduce Delays & Added Costs

We offer a complete injection molding solution with an in-house Technical Services team that supports clients with material selection by application, part design assistance to optimize manufacturing costs and part performance, injection mold / tooling design, value engineering, mold flow analysis, and finite element analysis.

USA Owned & Operated Injection Molding Partner

We are a USA-owned and operated ISO certified molder specializing in high-performance plastics molding in a wide range of critical applications for many different industries backed by years of experience.. We are ITAR registered and are a Defense Federal Acquisition Regulation (DFARS) CNC machined and injection molded plastic part supplier.

Onshoring Injection Molding Partner

We are an expert Onshoring partner for clients looking for a USA-based supplier to eliminate the common problems associated with Offshoring injection molded parts.

JIT Supply - Eliminate Lead Time Headaches and Part Inventory Costs

In addition, we offer JIT Just-In-Time supply and by supplying our clients parts as needed, just in time for production to eliminate their costs associated with carrying large on-hand inventories.