What is CNC Turning?

CNC (Computer Numerical Control) turning is a subtractive manufacturing machining technology that is performed by a CNC lathe. The lathe rotates bar stock material in a chuck with a cutting tool perpendicular to the bar stock which moves along a parallel axis to cut and contour the bar stock into a round part, to precise dimensions. CNC Turning Equipment comes in many different configurations with different options. Lathes that have live tooling can also perform drilling & milling operations.

When to use CNC Turning?

This process is ideal for round parts that are small to large sized parts with turning steps, low to high part volume, simple to medium complexity geometries with tight tolerances. For micro and small sized round parts with multiple features another turning process known as Screw or Swiss turning can provide a lower cost to manufacture with improved cycle times.

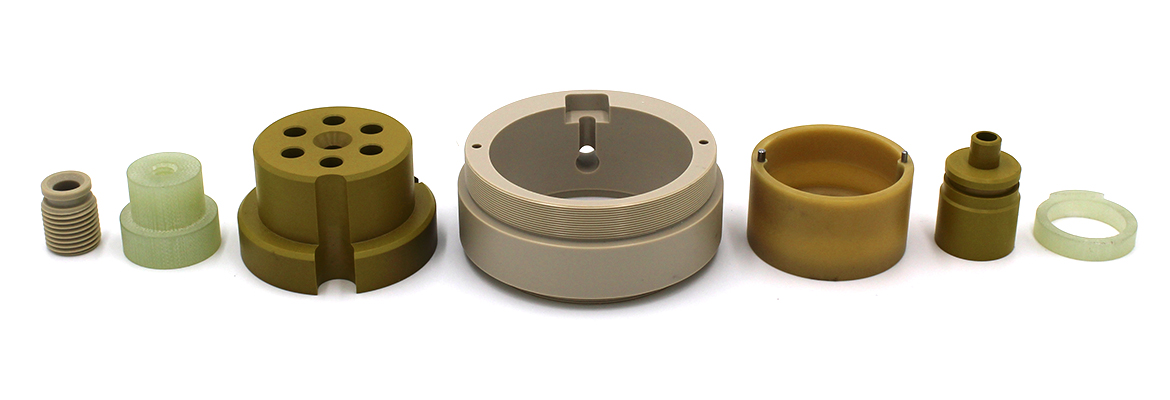

Why use Boedeker Plastics, Inc. for plastics or composite CNC Turning?

Our shop utilizes a wide range of turning technologies, including lathes with live tooling and turning centers capability backed by years of experience in plastics & composites only CNC turning. We have the experience, personnel & technology to provide reliable supply of high quality CNC machined plastic & composite parts. We also specialize in providing clients with Just in Time Supply (JIT) inventory services to help reduce inventory costs and provide parts as needed without long lead-times.

Our CNC Turning Equipment

- Cincinnati Milacron Falcon 200 Turning Center

- Hardinge GT27SP Gang Tool Lathe

- ROMI M-27 Lathe

- Trak TRL 1840 CSS

- Trak TRL 1840sx

- Trak TRL 2460sx (2)

Some of the Plastic & Composite Materials We Specialize in Machining Include: