PLAVIS® Polyimide Key Properties & Grades

PLAVIS polyimide has a unique chemical structure with some of the highest properties available. Nitrogen bonded to 3 carbons is the critical part of the chain and imparts the plastic with remarkable features and benefits.

PLAVIS polyimide delivers outstanding resistance to creep and lubricated or unlubricated performance, ultra-low outgassing, excellent mechanical strength and impact resistance. PLAVIS polyimide is applied in the industries of aircraft and aerospace, automotive, electrical and electronics, chemical and mechanical engineering, semiconductors, etc.

- High-temperature performance.

| | |

| - Good Electrical Properties - Insulative

| |

| | - Isostatically molded for uniform multidirectional performance.

|

PLAVIS® may be compared favorably to Vespel ® polyimide produced by DuPont.

PLAVIS ® N (comparable to Vespel ® SP-1)

- PLAVIS® N is the unfilled base resin grade. Plavis N provides maximum physical strength, elongation, and toughness as well as the best electrical and thermal insulation values. Typical applications include spacers, high-temp fixtures, valve seats, balls, gaskets, insulators, and seals. (see also Duratron D7000 PI)

PLAVIS ® G15 (comparable to Vespel ® SP-21)

- PLAVIS® G15 has 15% graphite by weight added to the base resin for increased wear resistance and reduced friction in applications such as bearings, thrust washers, bushings, seal rings, slide blocks and other wear applications. G15 has the highest mechanical properties of the graphite filled grades. (see also Duratron D7015G PI)

PLAVIS ® G40 (comparable to Vespel ® SP-22)

- PLAVIS® G40 has 40% graphite by weight for enhanced wear resistance, lower friction, improved dimensional stability (low coefficient of thermal expansion), and stability against oxidation. Typical uses are the same as those for G15.

PLAVIS ® MS (comparable to Vespel ® SP-3)

- PLAVIS® MS is 15% moly-filled (molybdenum disulfide solid lubricant) for wear and friction resistance in vacuum and other moisture-free environments where graphite actually becomes abrasive. Typical applications include seals, bushings, bearings, gears, and other wear surfaces in outer space, ultra-high vacuum or dry gas applications.

PLAVIS ® S (Comparable to Vespel ® SPC5000)

- PLAVIS-S offers improved thermal properties with continuous use of 350C / 662F, designed for demanding applications that require thermal and dimensional stability. PLAVIS-S offers higher tensile strength than PLAVIS-N and higher elongation at elevated temperatures.

PLAVIS ® ESD

- PLAVIS ESD offers static dissipative properties (surface resistivity 10^6 - 10^9 ohm/square) with high temp resistance and superior mechanical properties. Ideal for critical applications where static control is required in flat panel display and semiconductor applications.

PLAVIS ® C (Comparable to Vespel ® SP202)

- PLAVIS C Polyimide is the conductive grade (surface resistivity <10^3 omh/square) . Plavis C provides excellent physical strength, elongation, and toughness along with being conductive.

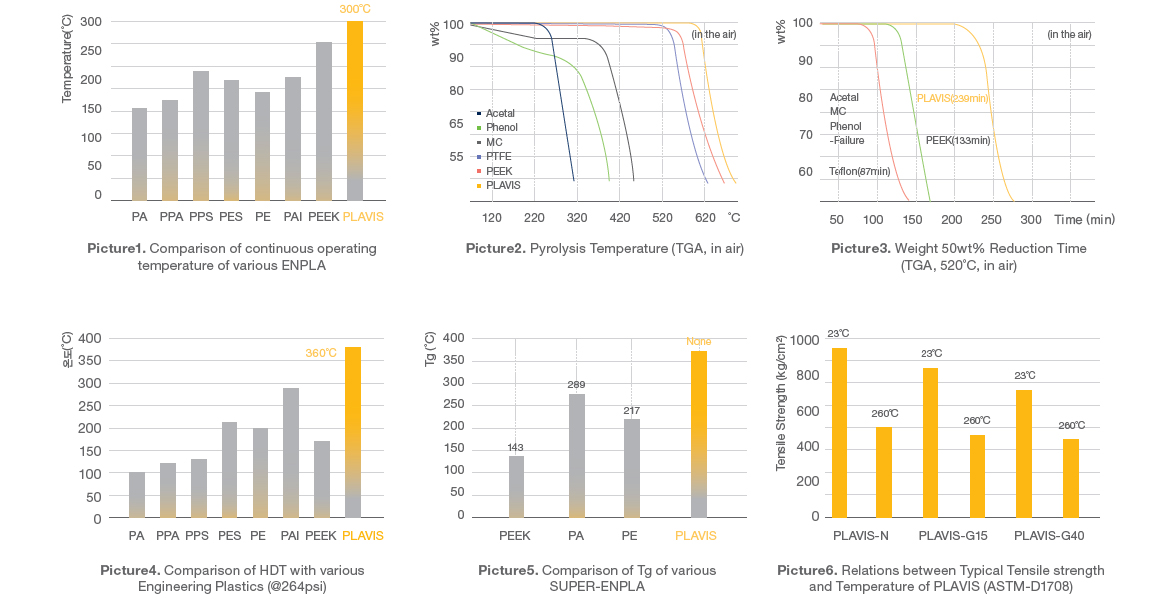

PLAVIS Offers High Heat Resistance

The main feature of PLAVIS is that it has no melting point with a continuous operating temperature of 300°C. Even at 370°C, a 50% reduction in tensile strength will not occur for 200 hours for PLAVIS-N (neat), 220 hours for PLAVIS-G15(15% graphite filled), and 360 hours for PLAVIS-G40 (40% graphite filled).

In a vacuum or oxygen void environment, the heat resistance of PLAVIS is even higher. Since PLAVIS has no melting point unlike other polyimides or ther-moplastics such as PEEK, PAI, PEI; the strength vs. temperature of PLAVIS is very linear and predictable. For applications where part dimensions and tolerances are critical over a range of temperature, PLAVIS is an excellent.