Phenolic Industrial Laminates Key Properties by Grade

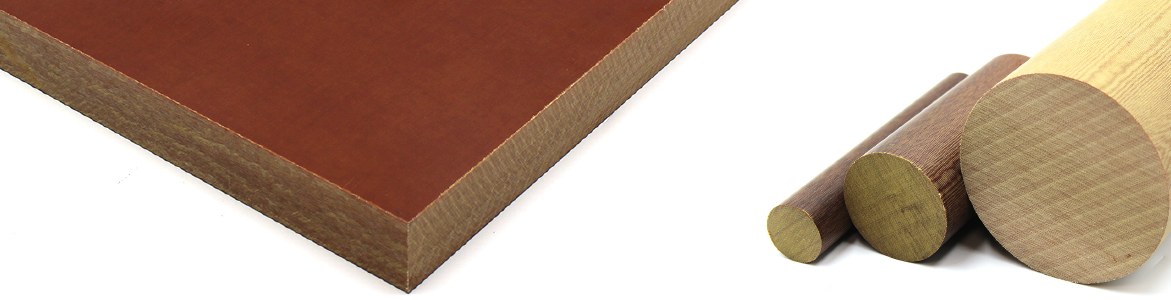

Offering excellent physical strength, resiliency, ease and versatility of fabrication, and excellent electrical properties make Phenolic Laminates useful as support components in a wide range of mechanical and electrical applications. Phenolic Laminates are strong, stiff, and have high impact and compressive strengths. And, they do not soften upon re-heating, so they are easy to saw, drill, tap, and machine with ordinary tools. Paper-based phenolics are the most economical of the laminates, yet provide significant electrical properties and good mechanical properties. For greater strength and machinability, cotton-fabric phenolics are often a good choice.

Phenolic X, XX, and XXX (Paper Base / Phenolic Resin)

Mechanical and Electrical grades are available which are excellent choices for intricate punch parts, insulating washers, spacers, terminal boards, switch bases, and other electrical components. The "X" designations generally distinguish manufacturing processes which result in different levels of electrical properties (i.e., dielectric strengths). Paper-based phenolics are available in a variety of sheet, rod, and tube sizes.

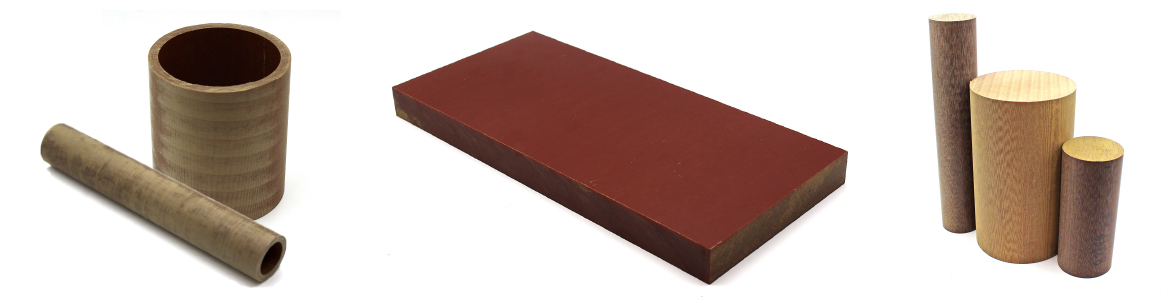

Phenolic C and CE (Canvas Base / Phenolic Resin)

Medium weave cotton cloth fabrics are mixed with phenolic resins to provide good wear resistance, low moisture absorption, and good mechanical strength at economical cost. Canvas-based phenolics are used for structural supports, piston rings, gears, spacers, and bearing surfaces. The "CE" grade has better electrical properties than the "C" grade. Canvas-based phenolics are available in a variety of sheet, rod, and tube sizes.

Phenolic L and LE (Linen Base / Phenolic Resin)

Fine weave cotton cloth fabrics are mixed with phenolic resins to provide better machinability than provided by the "C" and "CE" grades. The Linen-based grades also have higher density and good moisture resistance. "L" and "LE" phenolics are used for fine tooth gears, relay bases, radio parts, terminal bases and strips, often in high-humidity environments. The "LE" grade has better electrical properties than the "L" grade. Linen-based phenolics are available in a variety of sheet, rod, and tube sizes.

Military & Federal Specifications of Phenolic Laminates

*If you require certification to a MIL Spec it must be requested at the time of order.

Chemical Resistance of Phenolic Industrial Laminates

In general phenolic based industrial laminates offer excellent chemical resistance, but vary on chemical, concentration and other factors. For additional information on Phenolic linen or canvas based laminates and chemicals, Download Our Phenolic Industrial Laminate Chemical Resistance Guide If you require further assistance with a specific chemical or application specifics contact us, our Technical Staff stands ready to assist.

![]()

Boedeker Plastics, Inc. & Phenolic Laminates

We stock all commercial available grades of Phenolic Laminates and offer cut to size, same day shipping on all inventoried Phenolic materials. Our entire inventory of Phenolic Laminates is coded for full traceability, we offer manufacturer certs. and C of C’s upon request at the time of order for all orders. We specialize in plastics-only machining and produce CNC machined Phenolic parts for prototype to production quantities.

We also specialize in technical services for Phenolic Laminates and parts including: material selection by application, part design assistance & machining support, onsite consultation and more.

As an alternative to onsite consultation we offer our TelePlastics™ remote support service. This is a safe and secure remote solution, for the diagnosis and recommendation of plastic solutions, by our experienced Technical Service staff, utilizing the latest in telecommunication technology.

We stand ready to put our 1,800 years of combined experience and services to work for you.

![]()